Part Lists Maintenance & Updates

Optimising Part List Maintenance with RPA Automation

Key Solution: Robotic Process Automation (RPA)

Challenge

High Data Volume and Manual Labour: Maintaining and updating part lists involves processing over 5000 records manually, which is time-consuming and labour intensive.

Error-Prone Processes: Manual data entry often leads to errors and omissions, introducing operational risks that can disrupt manufacturing workflows.

Solutions

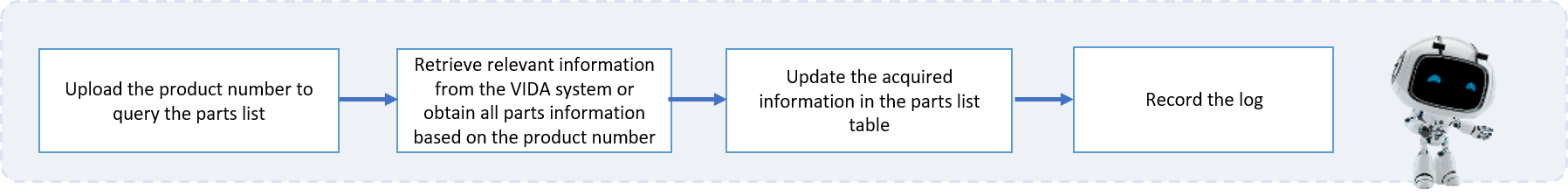

RPA automates part list maintenance by processing thousands of entries accurately and continuously, eliminating manual intervention and optimising efficiency.

Before Implementation:

- 8 hours per processing cycle, requiring continuous manual data entry.

- Over 5000 entries handled manually, leading to potential errors and omissions.

- Time-consuming and labour-intensive, increasing operational risks and hindering productivity.

- Prone to human errors and omissions, resulting in operational risks.

After Implementation:

- Fully automated processing requiring no manual labour, operating continuously.

- 5000+ entries processed automatically with consistent, error-free execution.

- 100% efficiency increase through continuous, rule-based automation that liberates manpower.

- Achieves 100% accuracy with rule-based automation, eliminating manual data entry errors.

Impact

100% Accuracy

100x Efficiency